MITUTOYO - Portable Surface Roughness Tester : SURFTEST SJ-410 Series | JSR GROUP

Portable Surface Roughness Tester

SURFTEST SJ-410 Series

User benefit

1 Easy and safe measurements that anyone can perform efficiently

The auto-set unit* enables measurements to be made with a single button push, saving you time and increasing work efficiency.

|

The auto-set function safely controls descent of the detector, eliminating the possibility of operator error causing damage to the stylus. |

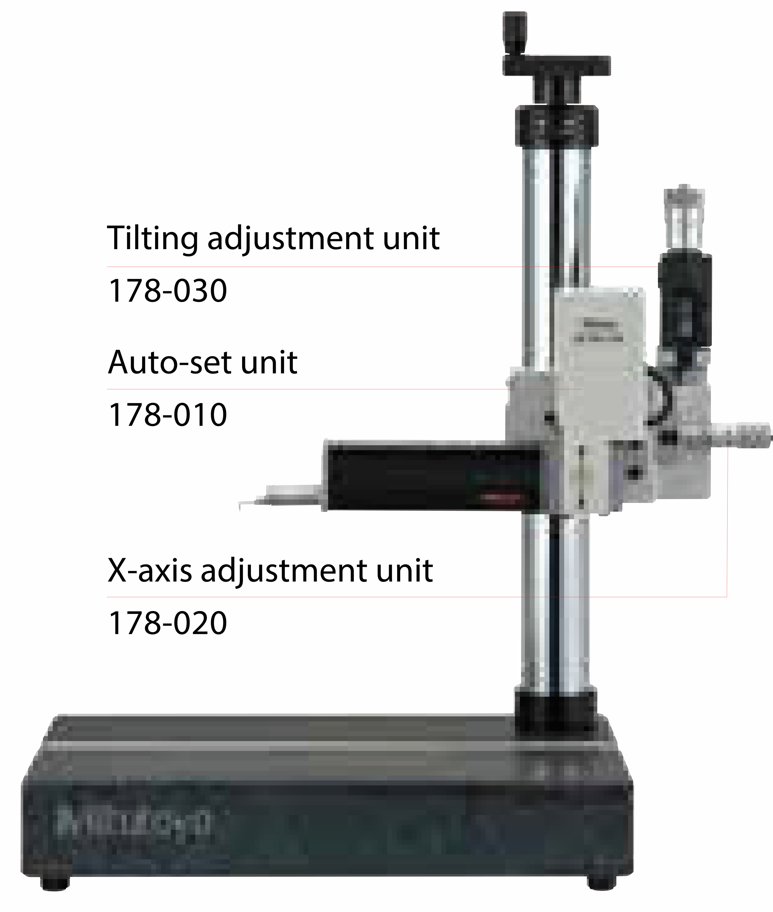

Auto-set unit* 178-010 This unit automatically completes a full measurement cycle of stylus contact, measurement, stylus retraction and detector auto-return from just one button push (stylus retraction and detector auto-return can be switched on and off by operating the drive unit).

|

| Options for SJ-410 Series |

|

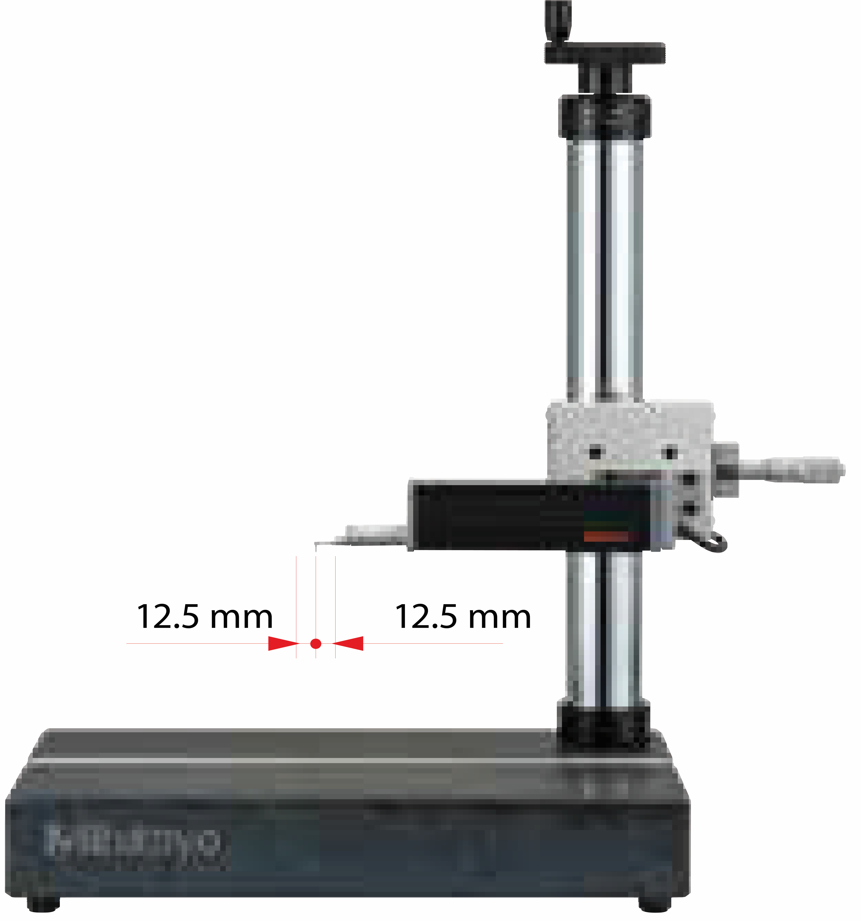

X-axis adjustment unit*

|

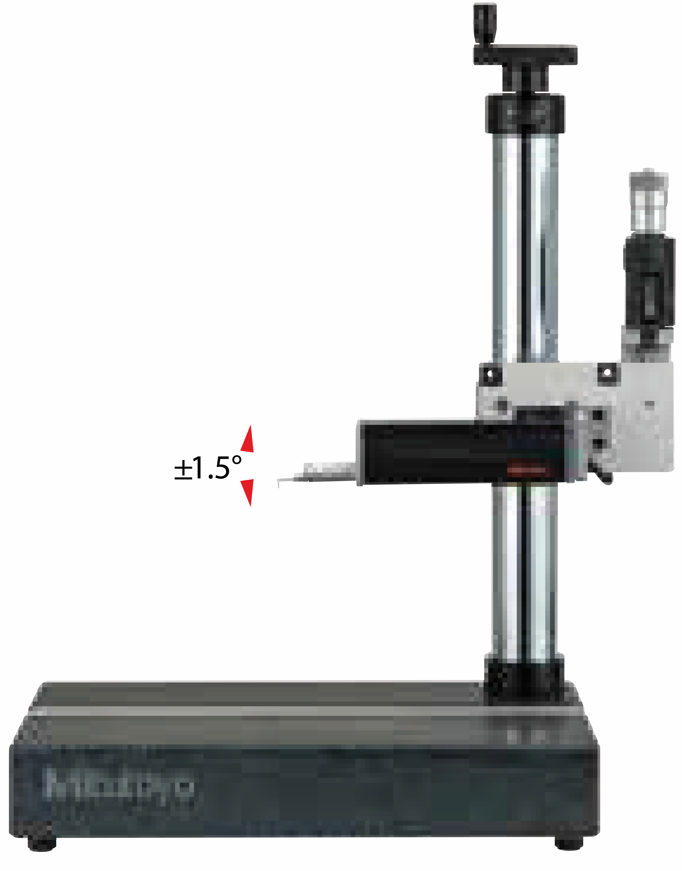

Tilting adjustment unit*

|

Complete set*

|

* This is an optional accessory for the SJ-410 Series. It can only be used on the simple column stand (optional accessory, order No. 178-039). When the units are used in combination, straightness for SJ-411/412 drive unit will be degraded about 0.2 µm. Cannot be used when the tester’s main unit is an older model (SJ-401/402)

| Assessing a single measurement result under two different evaluation conditions |

| A single measurement enables simultaneous analysis under two different evaluation conditions. A single measurement allows calculation of parameters and analysis of filtered profiles without the need for recalculation after saving data, contributing to higher work efficiency. |  |

| 3-axis Adjustment Table <Option> 178-047 |

|

|

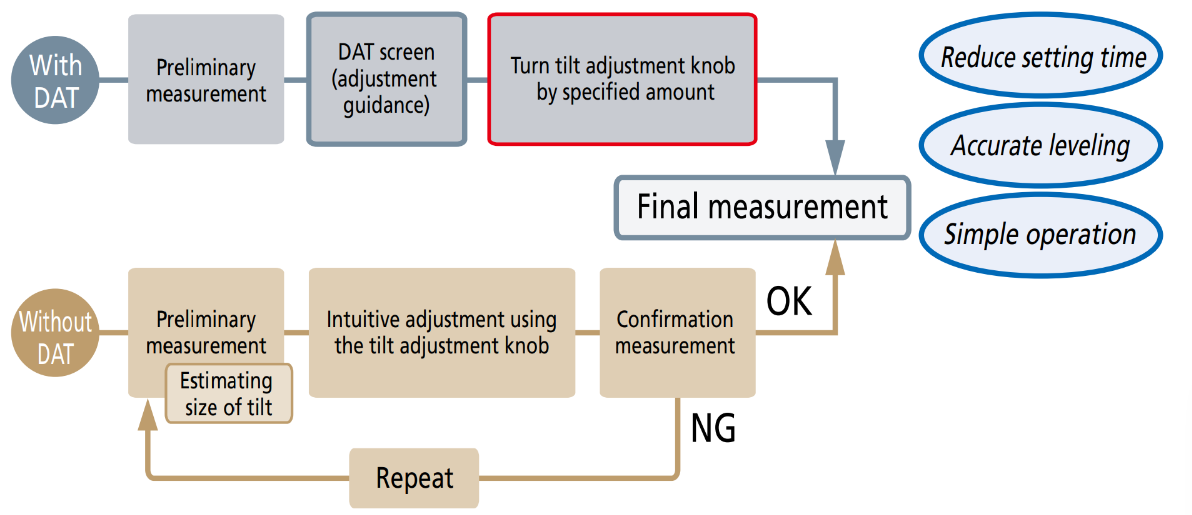

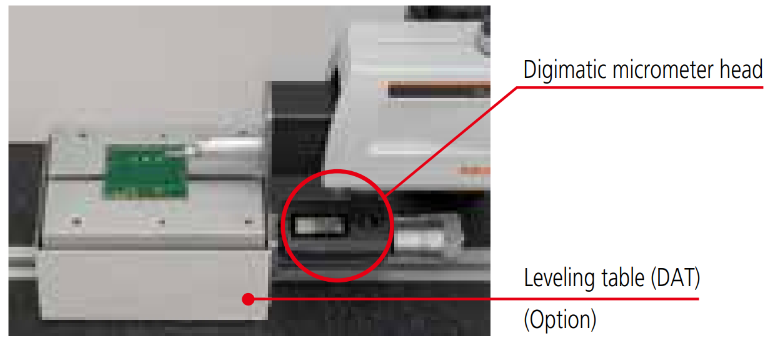

| DAT Function for the leveling table <Option> |

The levelling table can be used to align the surface to be tested with the detector reference plane. The operator is guided through the procedure by

screen prompts.

|

178-048 |

|

| Powerful support for leveling | Simple column stand for SJ-410 Series <Option> | |

|

The height/tilt adjustment unit comes as standard for leveling the drive unit prior to making skidless measurements and, supported by guidance from the unique DAT function, makes it easy to achieve highly accurate alignment.

|

178-039

|

User benefit

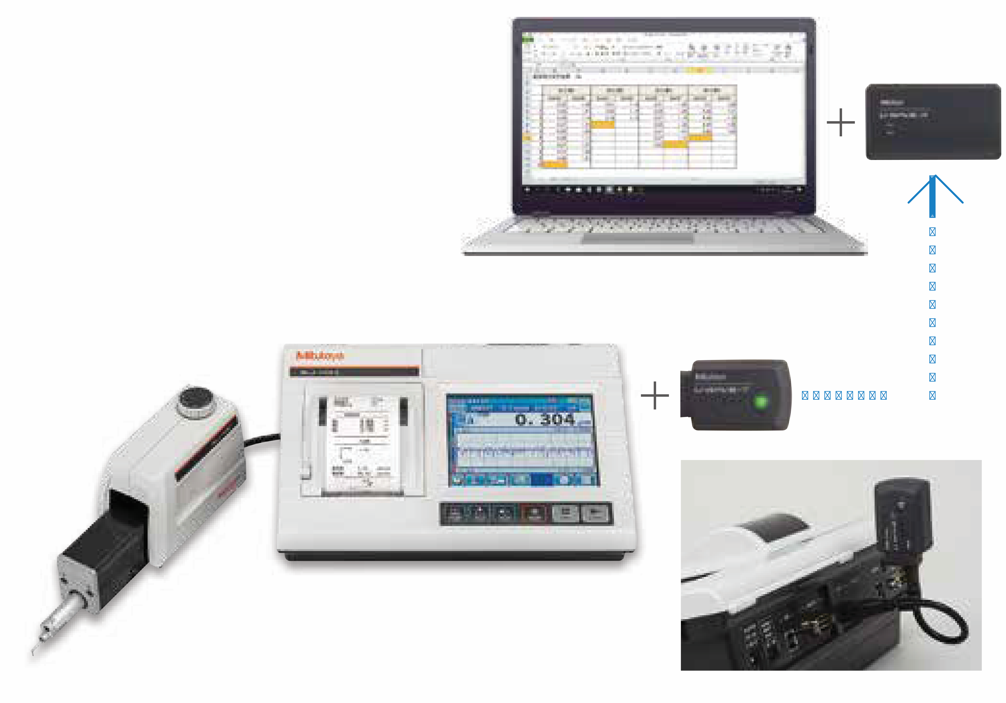

2 Higher level of quality control Wireless communicationand advanced analysis

Anyone can easily perform high-level data collection

| Wireless and quick capture of measurement results on a PC. No more handwriting, and also easy data input with a single touch <Option> |

|

Wireless Input Tool U-WAVE |

|

One-touch Input USB Input Tool |

| This unit allows you to remotely load Surftest SJ-410 calculation results (SPC output) into commercial spreadsheet software on a PC. You can essentially use a one-touch operation to enter the calculation results (values) into the cells in the spreadsheet software. | This unit allows you to load Surftest SJ-410 calculation results (SPC output) into commercial spreadsheet software on a PC via a USB connector. You can essentially use a one-touch operation to enter the calculation results (values) into the cells in the spreadsheet software. | ||

|

U-WAVE-R (Connects to the PC) |

U-WAVE-T* (Connects to the SJ-410) |

USB Input Tool Direct USB Input Tool DirectUSB-ITN-D 06AFM380D |

USB keyboard signal conversion type* USB keyboard signal conversion type*IT-016U 264-016-10 * Requires the optional Surftest SJ-410 connection cable. 1 m: 936937 2 m: 965014 |

| More advanced analysis with optional software. Also, easy creation of inspection record tables by transferring data to Excel |

|

|

Required environment* | |

| OS: Windows 7 Windows 8 Windows 10 |

Spreadsheet software: Microsoft Excel 2010 Microsoft Excel 2013 Microsoft Excel 2016 |

||

| * Windows OS and Microsoft Excel are products of Microsoft Corporation. | |||

| The optional USB cable is also required. | |||

| USB cable for SJ-410 Series 12AAD510 | |||

Contour/Roughness analysis software

FORMTRACEPAK-AP

More advanced analysis can be performed by loading SJ-410 Series measurement data to software program FORMTRACEPAK-APvia a memory card (option) for processing back at base.

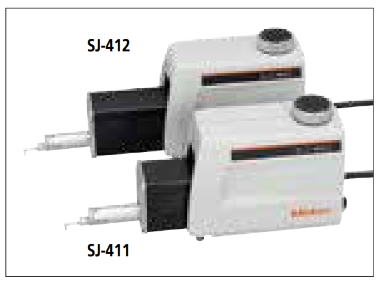

| Higher accuracy measurements with selectable drive unit | Extending measurement to narrow features | ||

|

A wide range, high-resolution detector Detector Measuring range/resolution: High straightness drive unit Drive unit Straightness/traverse length: |

|

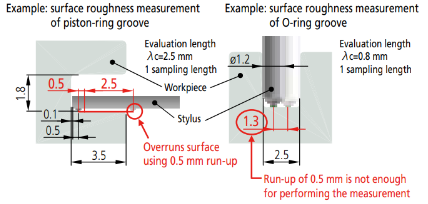

Surface roughness measurement requires a run-up distance before starting the measurement (or retrieving data). When the SJ-410 Series measures, its run-up distance is normally set to 0.5 mm. However, this distance can be shortened to 0.15 mm using the narrow-part measurement function. This function extends the measurement of narrow locations to features such as piston-ring grooves and O-ring grooves. Typical applications

|

|

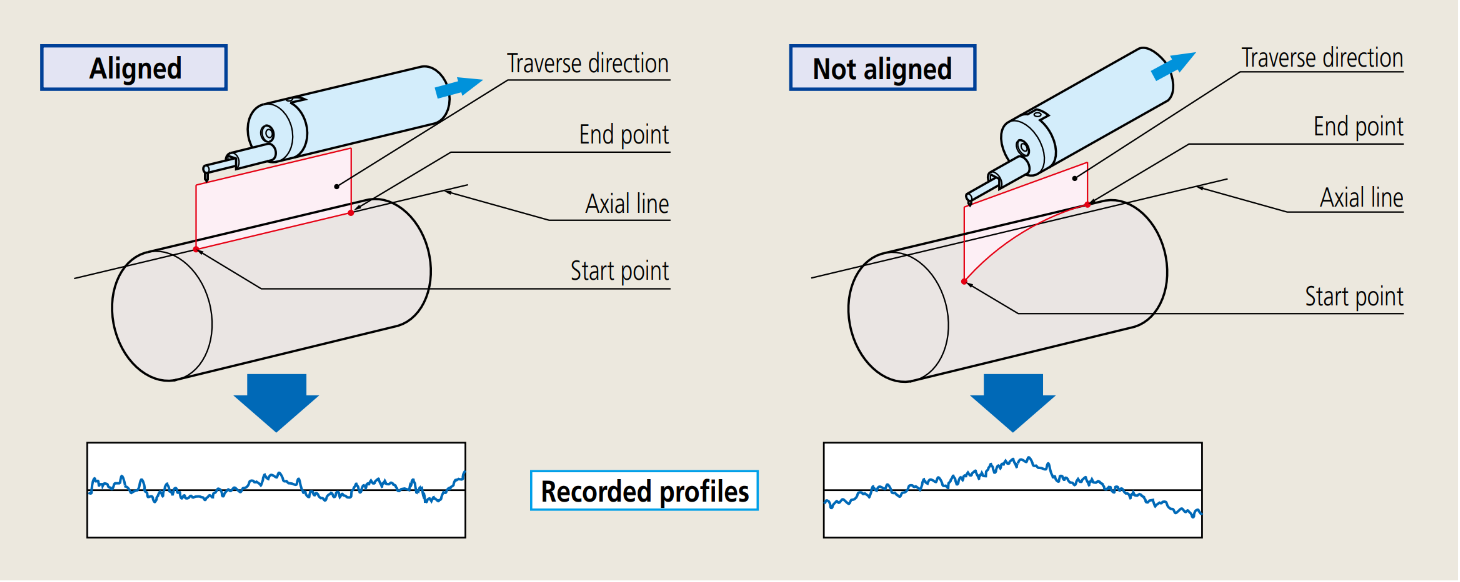

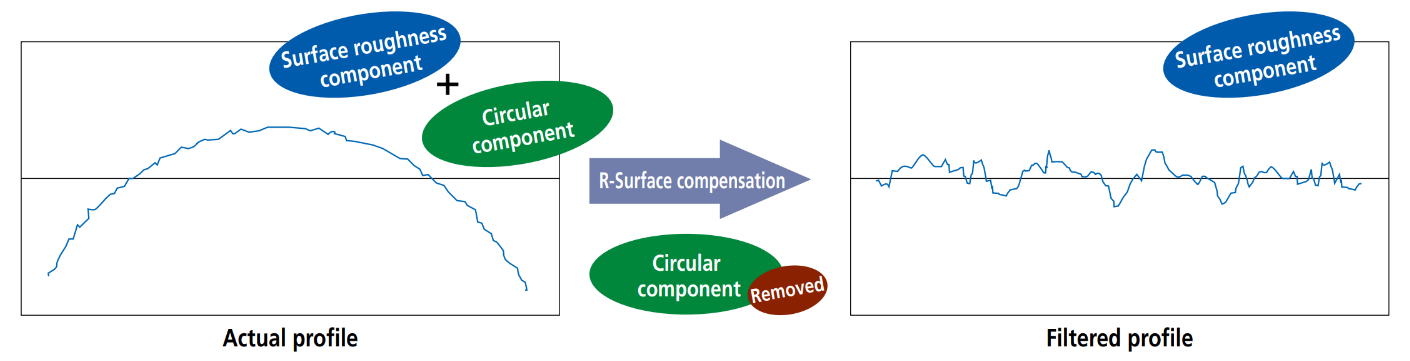

| Easily measures R-surface roughness (skidless measurement) |

Usually, a spherical or cylindrical surface (R-surface) cannot be evaluated, but, by removing the radius with a filter, R-surface data is processed as if taken from a flat surface

Other curved surfaces can be processed besides cylindrical, such as parabolical and ellipsoidal.

|

|

User benefit 3

Doing double duty for space saving Surface Roughness/Fine Contour

Supporting not only surface roughness measurement but also contour (fine contour) measurement

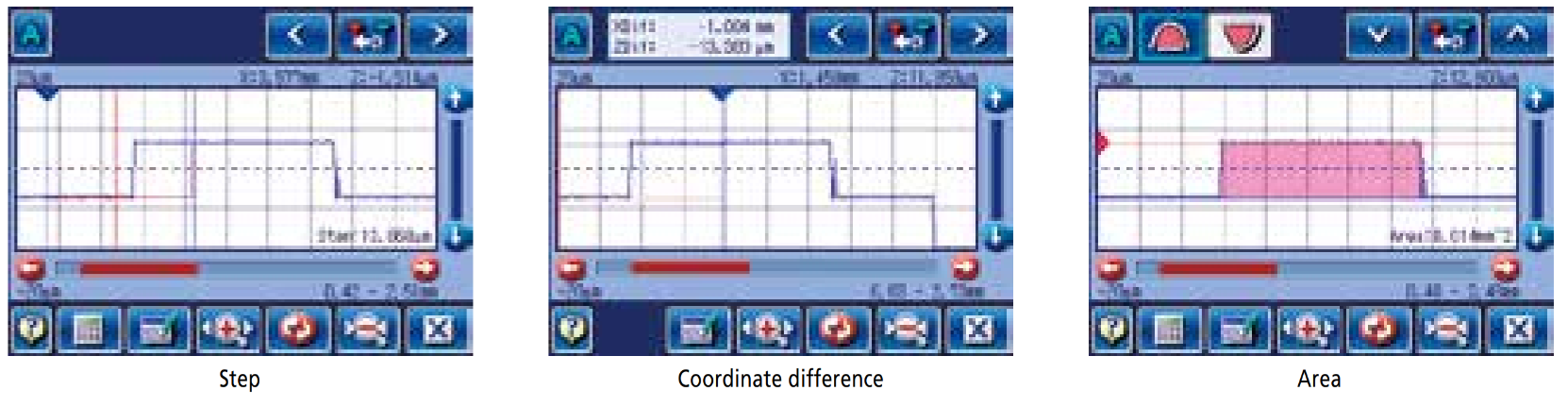

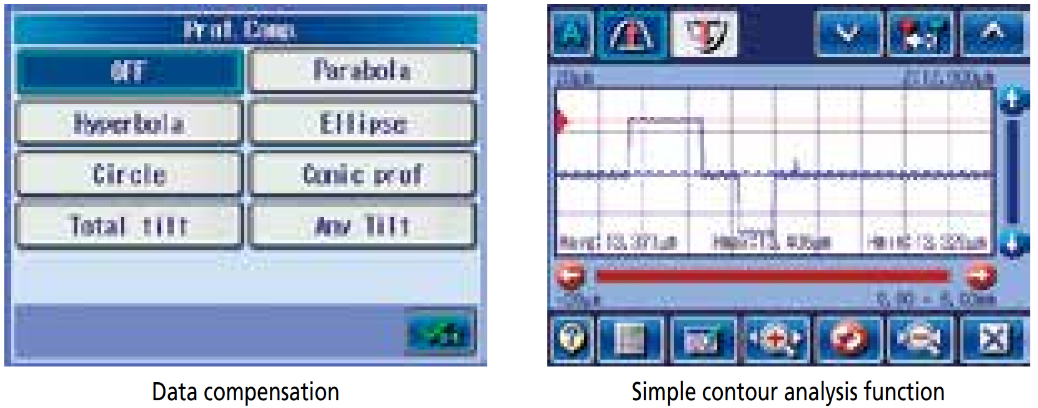

| Simple contour analysis function |

Point group data collected for surface roughness evaluation is used to perform simplified contour analysis (step, step height, area and coordinate difference). It assesses minute forms that cannot be assessed by a regular contour measuring machine.

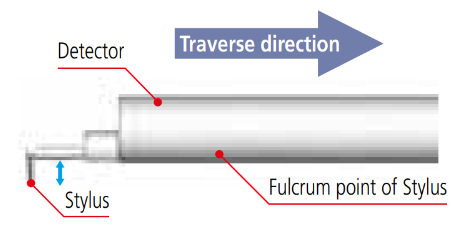

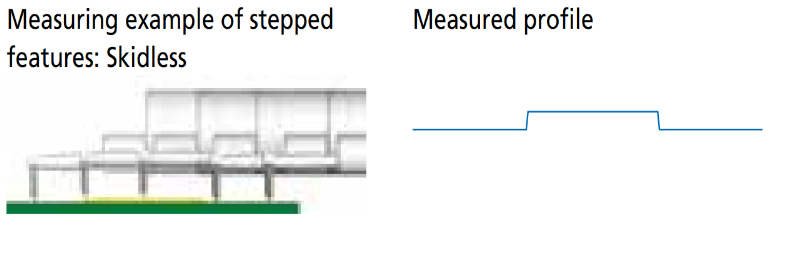

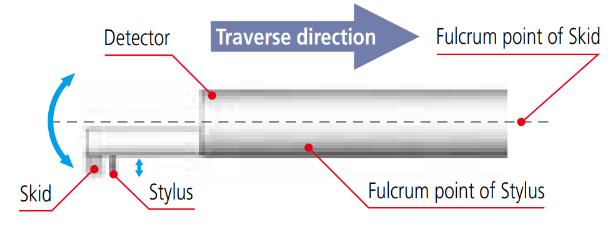

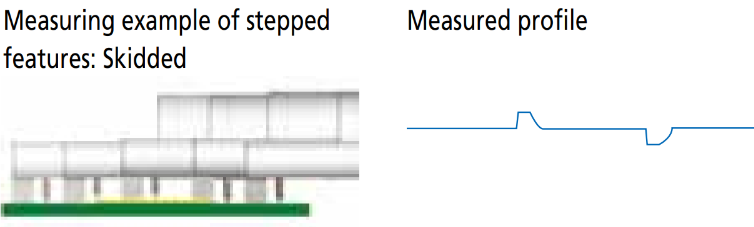

| Your choice of skidless or skidded measurement |

|

Skidless measurement

|

Skidded measurement

|

| Easy to use and highly functional |

| This portable surface roughness tester is equipped with analysis functionality rivaling that of benchtop surface roughness testers. |  |

| Equipped with externally controllable interfaces as standard | Data storage | ||

|

A variety of interfaces supplied as standard

|

Memory card (optional) is supported Measurement condition |

||

| Equipped with externally controllable interfaces as standard | Data storage | ||

|

High-speed printer prints out measurement results on site

|

The unit is easily transported in a dedicated carrying case which includes holders for the accessories as well as the tester itself. (Standard accessory)  |

||

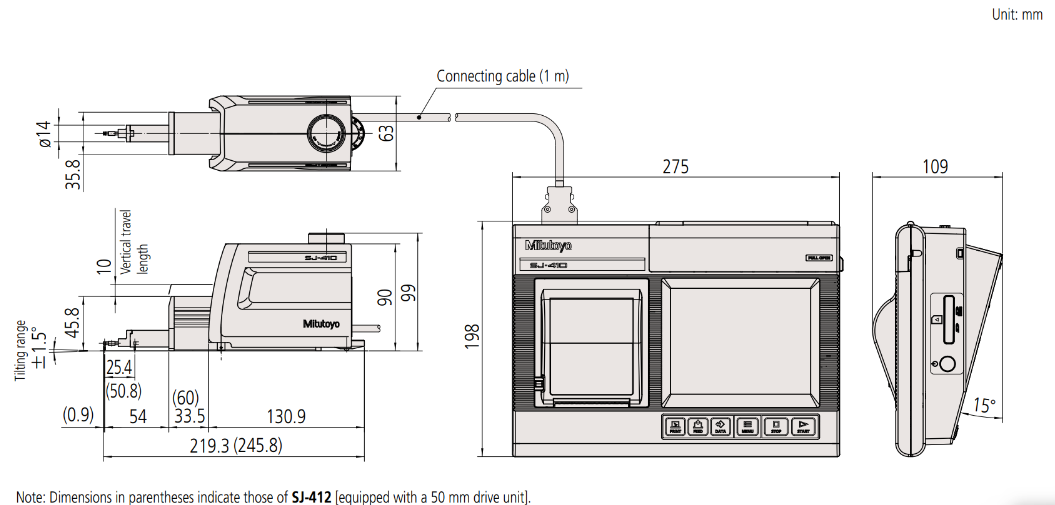

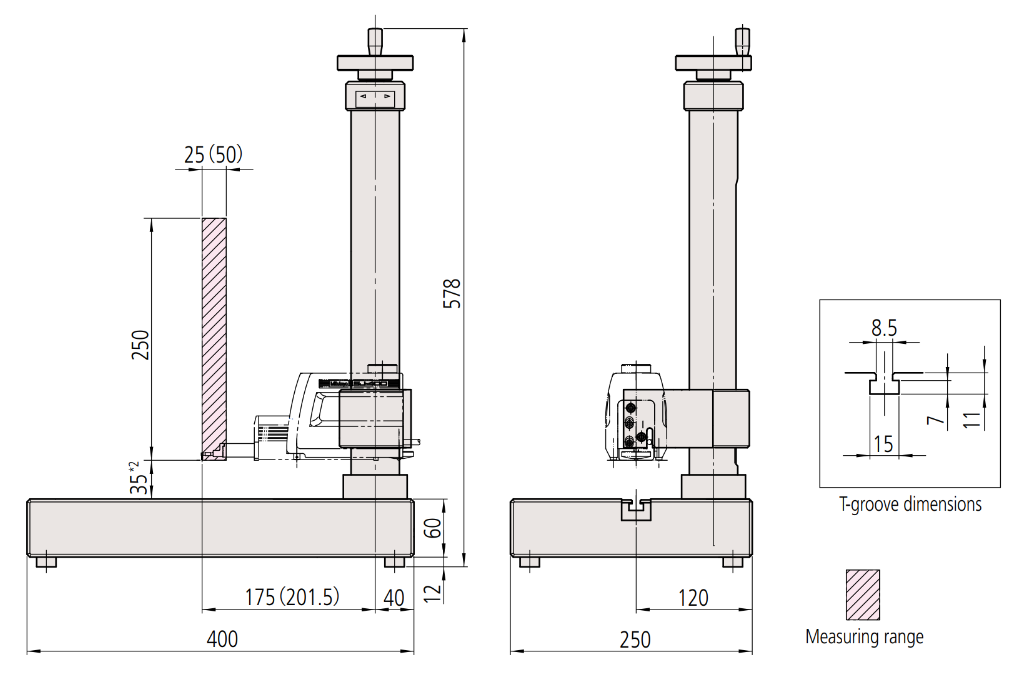

Dimensions

Example of mounting on simple column stand. (178-039)*1

*1 For details see page 5

*2 This is the lowest position of the standard stylus mounted on the simple column stand. Since it is 35 mm from the base top, a block of suitable height is required for calibration with a roughness specimen. Use the stand in combination with optional accessories such as a leveling table (178-016) or an XY leveling table (178-024).

Note: The dimensions in parentheses indicate those for SJ-412